“Do you know one of the biggest reasons people avoid cooking at home?

They have dull knives that they can’t keep sharp.

Use it a few times… and it’s as dull as soup spoon.

It is a well-known fact that dull knives are more dangerous to use than sharp knives, because they require more force to cut through food, which leads to slippage and increased risk of cuts, punctures and gashes

On top of that, most mass produced knives are heavy, or just plain uncomfortable to hold.

A slicing with a quality chef knife should be like driving a Astin Martin… smooth, fast and fun.

These are but a few reasons why I launched the Octopod knife line, featuring Japanese steel… and now there is a limited time upgrade.

Why Japanese knives will make you go “gaga”

Allow me a quick minute of your time and you’ll come away a believer as I am.

A History of Sharp Precision:

In Japan, legit knives are made using a traditional forging method called "honyaki."

This method involves using a single piece of the highest-quality Japanese steel, typically a harder and more brittle steel such as blue or white steel, to create the blade.

The steel is heated to a high temperature and then shaped and hardened using hammering and quenching techniques. The blade is then sharpened and polished by hand to create a razor-sharp edge.

This process is the “secret sauce” to their overall performance and longevity.

One of the key characteristics of honyaki knives is that they are made from a single piece of steel, which gives them a higher level of sharpness, durability and precision compared to factory made or “stamped” knives.

In addition, luxury Japanese steel chef knives are made with a great attention to details and many of them are made by skilled artisans with years of experience.

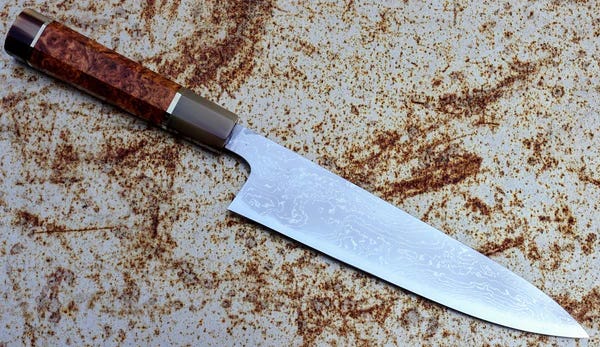

The handle of the knife is also of great importance, usually made of precious woods, horn or bone to create a luxurious look and feel to the knife.

It is a time-consuming and skillful process, but the end result is a knife that is highly prized by professional chefs and serious home cooks for its exceptional sharpness, durability, and beauty.

What Most Cooks are Used To?

Factory made, or mass-produced, knives.

These are often made with lower-quality materials, such as lower-grade stainless steel, that may not hold a sharp edge as well or be as durable as knives made with higher-quality materials. Also a higher chance of improper heat treatment which can affect their ability to hold a sharp edge (dull faster) and make them more prone to chipping or breaking.

Further, assembly line production may be more efficient for churning out numbers but the end product will not be as precise or well-crafted as knives made by hand. Many of these factory blades have a burr on the blade straight out of the box which automatically results in a dull blade after the first use.

Finally, mass produced knives not be properly balanced, which can make them uncomfortable to use and less efficient for certain tasks.

“Bigger” Isn’t Better

I remember falling in love with Japanese hand-made blades not only for the sharpness but because they feel so light in the hand, the knife feels like an extension of your arm.

This is exactly how a quality knife should feel in the hands of a cook. Effortless, smooth and automatic.

You’ll hear professional chefs say “let the knife do the work”, so then why do I want to be lugging around a heavy blade that feels like a weight?

This is my beef with European knives.

Lighter weight Japanese chef knives often have a different center of gravity, and balance, than heavier European knives which makes them better for tasks that require precision and control. You feel nimble and agile with the blade in your hand.

The blades themselves are also thinner which means less resistance and friction when cutting through ingredients.

Did you know lighter weight Japanese chef knives are often preferred by home cooks who want a knife that is easy to handle and maneuver for everyday use?

Ultimate Comfort:

You’ll notice on most high end Japanese forged knives an octagonal handle, known as a “Wa” handle.

Once you use these style of handles there’s no going back. They are extremely ergonomic but also balance the blade’s center of gravity to encourage smooth and effortless slicing, dicing and chopping.

These are but a few reasons that handmade, Japanese knives are my go to in my kitchen for the ultimate cooking experience

For you, I’m bringing the Ultimate in handmade Japanese craftsmanship.

Since launching the Octopod Classic chef knife I’ve had many requests for a Damascus or higher-end offering.

Now, for a limited time only, you can get a piece of handmade artistry and function.

Experience the difference of a truly high-end chef knife, hand-forged by a master craftsman for unparalleled quality

The Octopod Elite Limited series is live… for 72 hours only.

How it Works:

This is a one-time drop of collaborations I’ve done with the finest blade smiths in Japan.

These blades are completely custom… from the metals to the handles… all custom.

Just as every Bentley steering wheel is hand stitched to ensure complete luxurious quality, the same craftsmanship and artistry was put into making these one-of-a-kind knives.

There are 13 blades in this drop. Most one-offs.

Once they are gone… they are gone.

As a substack subscriber you are getting first option these, as I will not announce on social media until 12 hours after launch. ❤️

Each product page has a detailed description of the blade and handle.

These blades will last a lifetime and should be considered family heirlooms to be passed down.

Here’s a sneak peak:

One important note to make is that these blades are free shipping; the blade will ship 5-10 business days after purchase.

Most importantly, you can be purchase with “Buy Now Pay Later” installments on checkout.

This opens the playing field for more people who want to budget this out.